Overview

Currently, the global energy crunch and the growing emphasis on environmental protection have made the improvement of energy efficiency and the development of renewable energy sources two key aspects of sustainable energy development. Renewable energy sources, such as wind and solar energy, are receiving increasing attention and are considered to be the most promising avenue for the large-scale development and application of “green energy”.

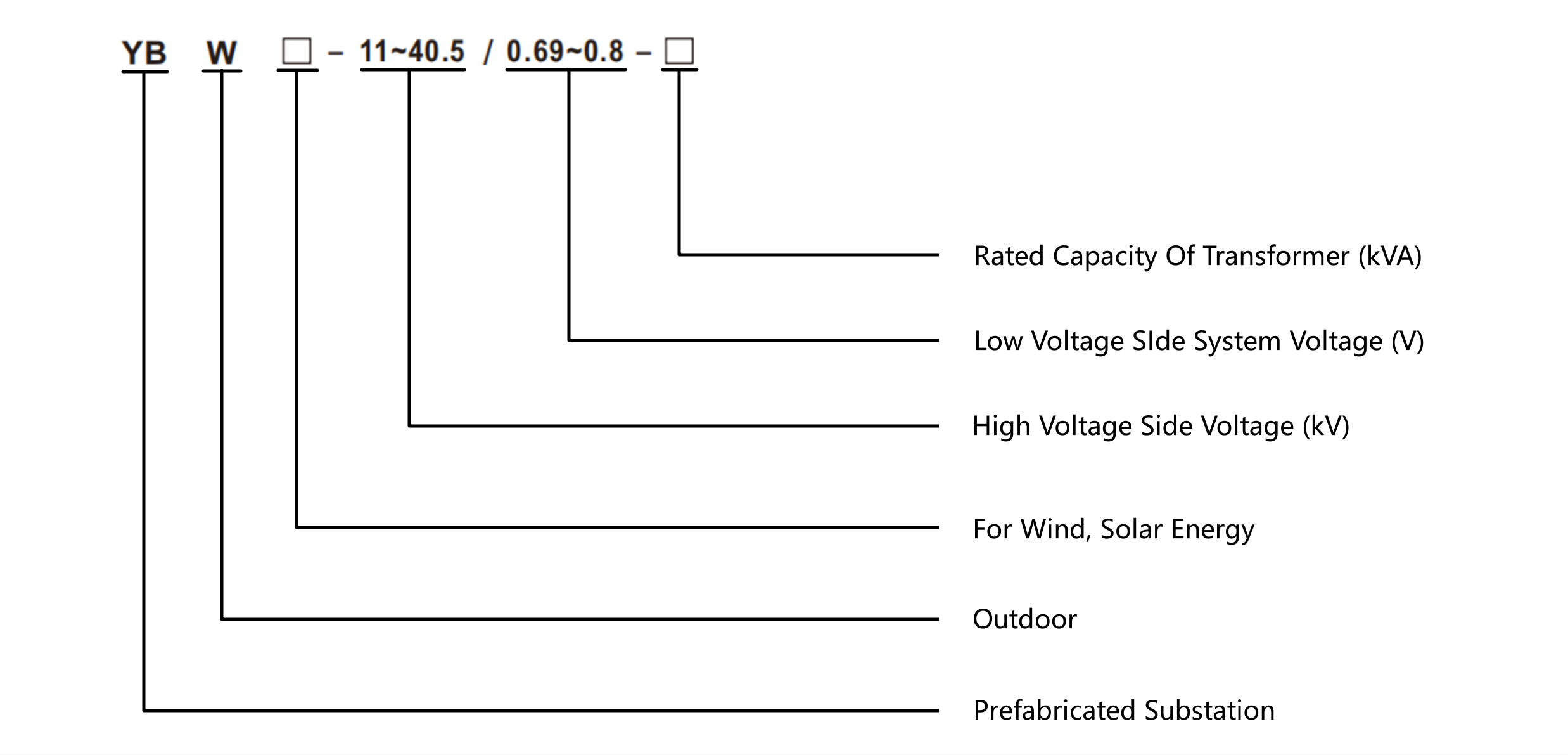

In China, in order to transmit electricity over long distances, the export voltage of wind or photovoltaic (PV) generating units needs to be boosted to 690 V. Typically, cables are used to connect the generators to specialized box-type step-up transformers. These transformers step up the voltage to 40.5 kV or 12 kV, which is then transmitted to the central substation of the wind or PV farm. The voltage is then further boosted and the power is fed into the grid.

Therefore, our company designs and develops 40.5 kV and 12 kV wind power step-up transformers and photovoltaic step-up transformers to meet these requirements and to achieve optimum performance.

Working Conditions

- Altitude not exceeding 1000 meters.

- Ambient temperature not more than + 50 degrees Celsius and not less than -25 degrees Celsius.

- Relative humidity: Average daily humidity not exceeding 95%, average monthly humidity not exceeding 90%,

- Monthly average humidity not exceeding 90%, monthly average humidity not exceeding 90%. Outdoor wind speed does not exceed 35 meters per second.

- No fire and explosion hazards, serious pollution, chemical corrosion, or severe vibration at the installation site. A small amount of dust, smoke, salt spray and corrosive gas pollution,

- A small amount of dust, smoke, salt spray and corrosive gas pollution is allowed, and the degree of pollution does not exceed Grade II.

- Seismic intensity: VII degree;

- Horizontal ground acceleration ≤ 0.2m/s; vertical acceleration less than 0.1m/s, safety factor 1.67.

Note: In the special use of the environment, when the use of the place beyond the requirements of the normal use of environmental conditions, the user needs to consult with the manufacturer.

Reviews

There are no reviews yet.