Overview

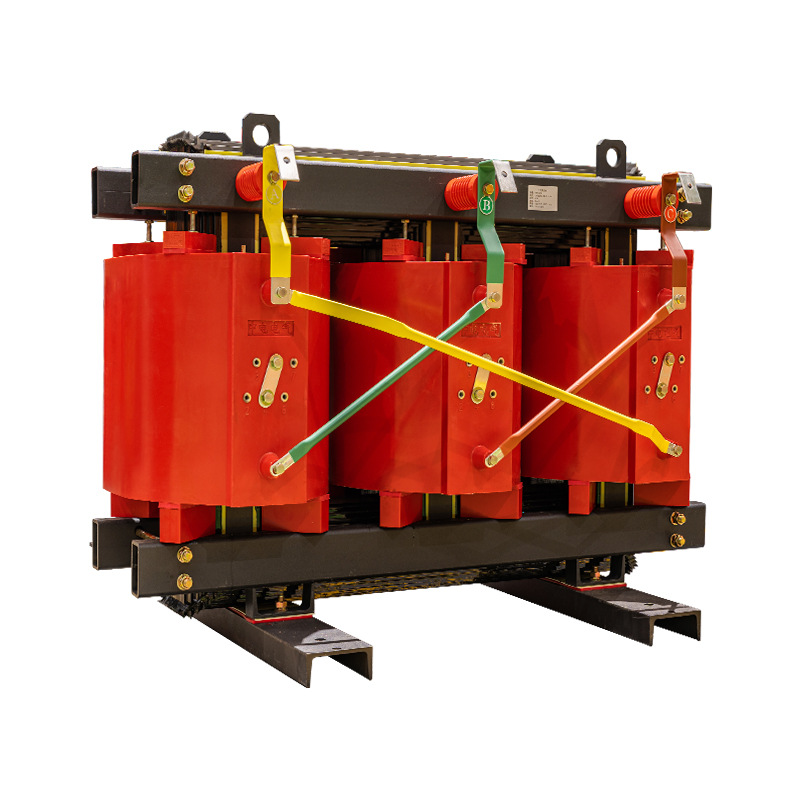

Cast Resin Transformers(Dry Type), because its coil is encapsulated by epoxy resin, so it is flame retardant, fireproof, explosion-proof, maintenance-free, pollution-free, small volume, can be directly installed in the load center. At the same time, scientific and reasonable design and casting process make the product partial discharge smaller, low noise, strong heat dissipation ability, under forced air-cooled conditions can be in 140% rated load for long-term operation, and is equipped with intelligent temperature controller, with fault alarm, over-temperature alarm, over-temperature trip and black gate function, and through the RS485 serial interface connected to the computer, can be centralized monitoring and control.

The products are widely used in power transmission and transformation systems, such as hotels and restaurants, airports, high-rise buildings, commercial centers, residential communities and other important places, as well as the subway, smelting power plants, ships, ocean drilling platforms and other places with harsh environments.

Cast Resin Transformers(Dry Type) core adopts high permeability high quality grain oriented cold rolled silicon steel sheet 45 ° full diagonal stepping seams, the core adopts special square tube pulling plate structure, the core column adopts insulating tape binding, the core surface is coated with special resin to prevent moisture and rust, which effectively reduces the no-load loss, no-load current and noise of the iron core.

Translated with www.DeepL.com/Translator (free version)

Product Features

- The core is made of imported high-quality cold-rolled silicon steel sheet with full diagonal joint structure, the core column is tied with F-class non-woven adhesive tape, the surface of the core is sealed with insulating resin paint in order to prevent moisture and rust, which reduces no-load loss, no-load current and noise of the core, and the clamps and fasteners are made of special surface treatment, which further improves the quality of the product appearance.

- High-voltage windings are vacuum cast with epoxy resin with filler, which greatly reduces the local discharge and improves the electrical strength of the coil. The inner and outer walls of the windings are filled with fiberglass mesh panels, which strengthens the mechanical strength of the coil, improves the product’s ability to resist sudden short-circuits, and ensures that the coil will not be cracked.

- Low-voltage winding adopts foil structure, which solves the problem of axial helix angle when winding with wire and makes the ampere-turns more balanced. Meanwhile, the coil adopts axial cooling duct, which enhances the heat dissipation ability, and DMD epoxy resin prepreg is used in between the layers of winding, and the whole is cured and shaped.

- Adopt cross-flow top-blowing cooling fan, the cooling fan has the characteristics of low noise, high wind pressure, beautiful appearance, etc., which enhances the overload capacity of the transformer. The temperature control adopts intelligent temperature controller, which improves the safety and reliability of transformer operation.

- Protection shell for further safety protection of the transformer, protection level IP20, IP23, etc., shell material has cold rolled steel plate, stainless steel plate, etc. for users to choose. Low-voltage outlet line with standard bus discharge line, side outlet line and top outlet line can be, can also be designed for the user special outlet mode.

- According to different interface forms, we can manufacture regular outlet line, standard closed busbar and standard side outlet line, and we can also design special outlet line according to user’s requirements.