Hello everyone! If you’re grappling with AC Contactor failure symptoms, congratulations you have come to the right place.

This article focuses on AC Contactor troubleshooting solutions to reveal the mysteries of these devices to you. We have not only rated the ease of solving each fault and cost of repair, we will also provide you with detailed solutions to help you get rid of the problem.

Let’s explore together how easy it is to find a clear solution when faced with AC Contactor failure symptoms.

Understanding the Basics of AC Contactor

So, what’s an AC contactor? What are its internal structure and components like, and how does it work? Understanding the basics is key to mastering troubleshooting.

So, what’s an AC contactor? What are its internal structure and components like, and how does it work? Understanding the basics is key to mastering troubleshooting.

Contactor internal structure

Electromagnetic mechanism: generally consists of coil, moving iron core and static iron core.

Contact system: generally consists of main contacts and auxiliary contacts. The main contact is mainly used to connect the main circuit, usually three pairs of normally open contacts. The auxiliary contacts are mainly used to control the line. Therefore, also known as interlocking contacts, generally normally open, normally closed two pairs.

Arc extinguishing device: for larger capacity (generally 10A or more) have a special arc extinguishing system. And small capacity is often used double-break bridge contacts to extinguish the arc.

- Other auxiliary components: shell, spring, short-circuit ring, drive mechanism.

The working principle of the contactor

The working principle of AC contactor is that when the coil is energized, the static iron core generates electromagnetic suction, which sucks the movable iron core closed.

Since the contact system is linked with the movable iron core, the movable iron core drives the three movable contacts to run at the same time, and the contacts are closed, so as to connect the power supply.

When the coil is de-energized, the suction force disappears, and the linkage part of the movable iron core is separated by the reaction force of the spring, so that the main contact is disconnected and the power supply is cut off.

Identifying Common AC Contactor Failure Symptoms

Since the AC Contactor can be frequently turned on and off during the working process, it is inevitable that there will be wear and tear on the Contactor during the use. At the same time, sometimes improper use, or use in a relatively harsh environment, will also shorten the life of the Contactor or easily cause failure.

Pre-troubleshooting

- Always prioritize safety. And make sure to turn off the power to the entire system you are working on.

- Equip yourself with safety gear – goggles and gloves are essential. In addition to this other tools such as a multimeter, screwdriver, etc. need to be prepared

Now, let’s tackle the real deal – common problems that might be messing with your cool vibes.

AC Contactor fails to engage or disengage

Ease of Repair: ★★★

Replacement Cost: ★★★★

Cause: Electrical problem and mechanical failure.

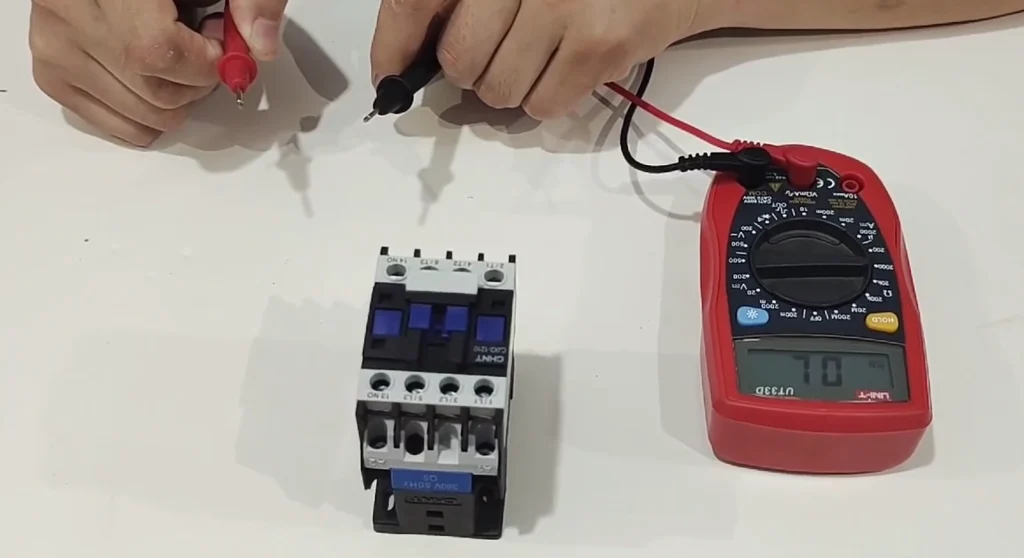

Solution: In general, you can first check whether the coil is disconnected. In the case of power failure, you can use a multimeter to measure whether the coil has a resistance value. Is the resistance value within the specified range.

Consider replacing the coil or lubricating the moving parts.

AC Contactor humming

Easy to repair: ★★★★

Replacement Cost: ★★★

Cause: Loose connection, damaged shorting ring, low supply voltage or stuck movable part.

Solution: Replace the short circuit ring, increase the supply voltage or remove the jammed part.

AC Contactor overheating

Ease of repair: ★★★

Replacement Cost: ★★★

Cause: Spring pressure is too small, oil on the contacts, high ambient temperature, contacts for long-term operation, the operating current is too large to cause the contacts to disconnect the capacity is not enough.

Solution: Adjust the contact spring pressure, clean the contact surface, use the contactor with reduced capacity, replace the contactor with larger capacity.

Welded contacts or AC Contacts keeps burning out

Easy to repair: ★★★

Replacement Cost: ★★★

Cause: Operating frequency is too high or overload use, short circuit at the load end, contact spring pressure is too small, mechanical jamming and so on.

Solution: Replace the appropriate contactor or reduce the load, eliminate short-circuit faults and replace the contactor, adjust the contactor surface pressure, and remove the obstruction.

AC Contactor chattering

Ease of repair: ★★★

Replacement Cost: ★★★

Cause: Voltage fluctuation or loose connection.

Solution: Stabilize voltage and tighten loose connections. Keep an eye on the wiring for damage.

The coil is overheated and burnt

Ease of repair: ★★

Replacement Cost: ★★★

Cause: Short circuit between turns of the coil, or inconsistency between the parameter when used and the actual, such as the rated voltage and the actual working voltage do not match. Or the iron core appears mechanical jamming.

Solution: Replace the coil or replace the appropriate AC contactor. Eliminate the jamming obstruction.

The contacts of the contactor cannot be reset

Ease of repair: ★★★

Replacement Cost: ★★★

Cause: The movable and static contacts are fusion welded together. Dirt or debris buildup or mechanical failure.

Solution: Replace the contacts. Clean these contacts and the mechanism. Lubricate moving parts and replace if necessary.

Insufficient contact pressure

Ease of repair: ★★★

Replacement Cost: ★★★

Cause: Weak springs or worn parts.

Solution: Inspect and replace these springs. Check and replace worn parts.

Conclusion

In short, some of the faults of the contactor is a gradual accumulation of formation, if we often patrol, carefully check, find the problem and timely repair and maintenance, we can avoid greater accidents. We can only elevate the height of the idea, pay attention to the problem in daily work, and actively take effective measures to greatly reduce the contactor failure, to ensure the safe and normal operation of the equipment.

In the meantime, if you are interested in [Getting Started Manual for AC Contactor Beginners], and [Solutions to all common failures of AC contactors], please do not hesitate to click on the links to see our other articles.

That’s it for today, we’ll see you in the next article.

Table of Contents

Have you Any Questions?

Can’t find an answer to your question, or want more information about our products? If so, please feel free to get in touch with our professional team. We’re here to help you drive your projects to success.