Introduction to Molded Case Circuit Breaker (MCCB)

Molded case circuit breakers (MCCBs) are essential components in low-voltage power distribution systems. They protect circuits by interrupting fault currents within a specified range. However, many users lack a clear understanding of MCCB characteristics and parameters, which leads to misapplications and confusion.

This article provides a detailed explanation of the key parameters and selection considerations to help users choose and use MCCBs effectively.

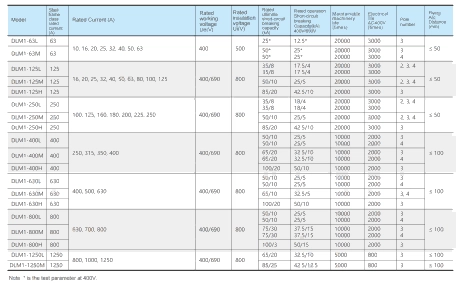

Rated Parameters Reference Table of Molded Case Circuit Breaker

Before diving into specific concepts, we’ve prepared a comprehensive table of rated parameters for circuit breakers for your reference.

The parameters in this table are based on our DLM1 Series Molded Case Circuit Breakers. If you have any questions, please feel free to contact us.

If you are interested in purchasing molded case circuit breakers, you may email us directly with the required specifications and quantities. We will provide you with a professional quotation as soon as possible.

Understanding Shell Frame Classes of Circuit Breaker

Each MCCB frame size can accommodate various rated currents. The rated current of a circuit breaker is the maximum current its trip units can carry continuously. The maximum value within a series is known as the shell-frame current.

In the same series, there are many kinds of shell-frame rated current, and there are many kinds of rated current in the same shell frame rated current.

For example, our DLM1 series MCCB has 63A, 125A, 250A, 400A, 630A, 800A, 1250A and 1600A shell-frame rated current. The shell-frame rated current of DLM1-125 are 16A, 20A, 25A, 32A, 40A, 50A, 63A, 80A, 100A, 125A. The shell-frame rated current of DLM1-250 are 100A, 125A, 160A, 180A, 200A, 225A, 250A.

Although DLM1-125 and DLM1-250 can both have 100A rated currents, their external dimensions, breaking capacities, and prices differ. Therefore, when choosing an MCCB, users must consider both available space and budget.

Selection Note

Specify both the shell-frame rated current and the actual circuit breaker rated current when selecting a model. This ensures compatibility and performance.

And in the actual selection for purchase, the model number should be filled out completely, that is, both the specific shell-frame rated current and circuit breaker rated current need to be filled completely.

Choosing the Correct Rated Current of Circuit Breaker

Rated current classification is selected according to (1.25) priority factor:

on the one hand, to comply with and meet the needs of the maximum line and electrical components rated current;

on the other hand, in order to standardize, in order to obtain the best use of the conductor and the benefits of processing.

For example: when the load calculated for the line is 90A, then it is better to choose the 100A size instead of 80A, because the rated current will affect the protection performance of the circuit breaker to some extent. When the budget is low and the reserved breaker size is not enough, it is recommended to choose DLM1-125 type instead of DLM1-250 type.

Rated Insulation Voltage and Working Voltage of Circuit Breaker

The rated insulation voltage is the highest voltage a circuit breaker can safely isolate under normal operating conditions. This value directly determines the breaker’s electrical clearance and creepage distance.

If the manufacturer does not specify the insulation voltage, the maximum rated working voltage should be considered its default insulation voltage.

Important: The working voltage must never exceed the rated insulation voltage.

Why Insulation Voltage Matters

The rated insulation voltage serves two critical functions:

- Withstanding Voltage Stress

It defines the maximum voltage the breaker can endure without breakdown. If the system voltage exceeds this rating, the breaker may fail, causing a short circuit or damaging electrical equipment.

- Ensuring Insulation and Safety Performance

A circuit breaker should withstand at least twice the insulation voltage during dielectric testing. This ensures proper insulation, prevents leakage, and maintains safety under both normal and fault conditions. The breaker must also react quickly to short circuits, protecting downstream equipment.

Choosing the correct insulation voltage helps the breaker maintain stable performance and protect your entire system.

How to Select the Right Insulation Voltage

When selecting a molded case circuit breaker, match the rated insulation voltage to your actual system requirements.

Always choose a value higher than the maximum working voltage of your circuit.

Take into account the rated current and load type (resistive, inductive, or capacitive).

For inductive or capacitive loads, consider overvoltage protection and interference suppression when determining the insulation requirement.

Rated Working Voltage Overview

The rated working voltage is the voltage level at which the breaker operates reliably under defined conditions.

Most MCCBs are rated for:

50 Hz, 380V

Some models support 50 Hz, 600V

Warning: Do not use a 380V-rated MCCB in a 660V power supply. This can lead to equipment failure and pose serious safety risks.

Rated Ultimate Short Circuit Breaking Capacity of Circuit Breaker

Rated ultimate short-circuit breaking capacity refers to the breaking capacity after the action according to the specified test procedure, without considering the ability of the circuit breaker to continue to carry its rated current.

In order to meet the needs of different users, we will be the same shell and frame level rated current short circuit breaking capacity is divided into different levels.

Such as DLM1-125 molded case circuit breaker has the following two levels of breaking capacity: L standard (17.5 ~ 35kA), M higher breaking type (25 ~ 50kA).

Users should choose suitable ultimate short circuit breaking capacity for the circuit breakers when selecting them, which need not be too high or too low to avoid waste under the premise of ensuring safety.

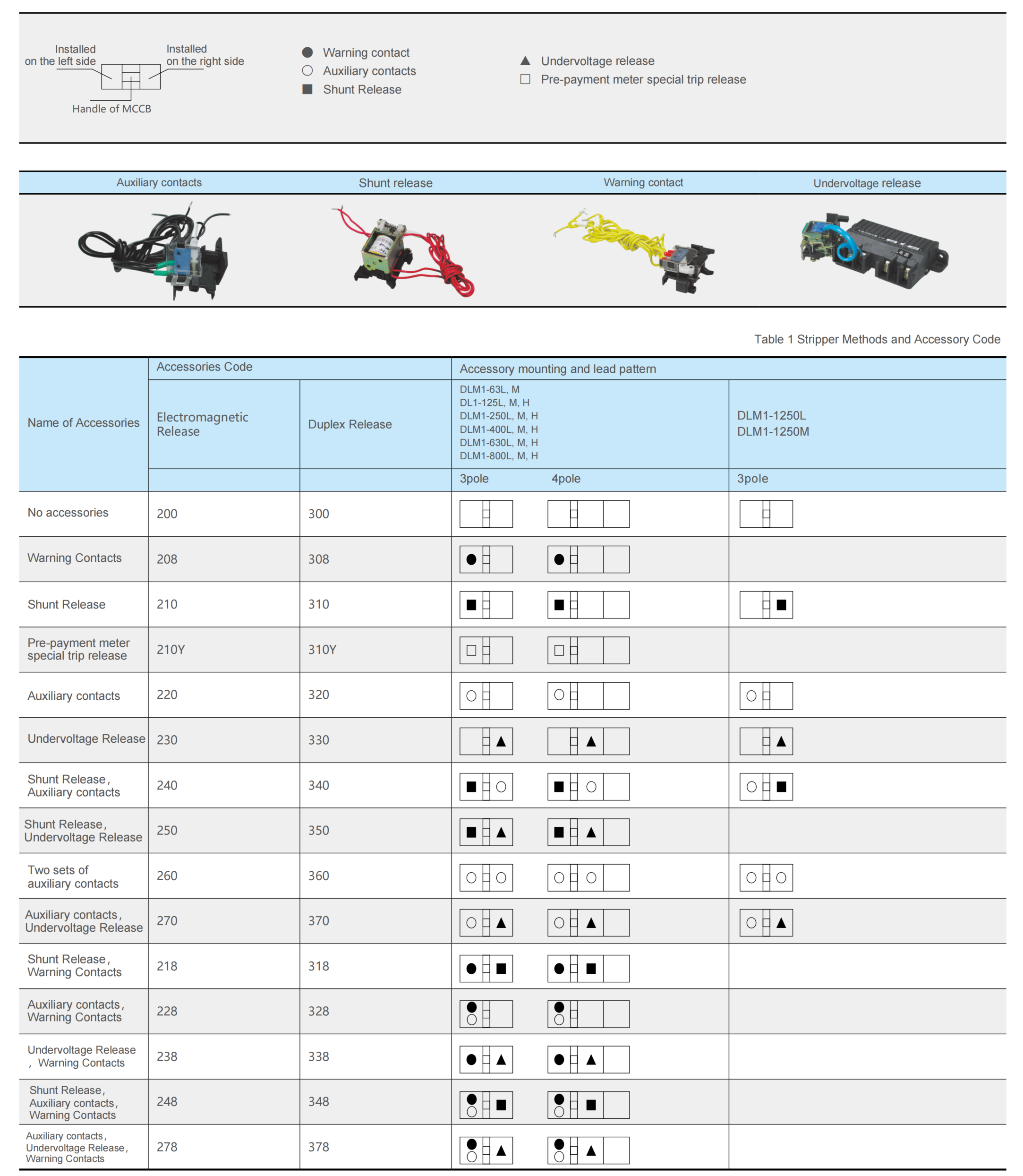

Functions and Types of Circuit Breaker Accessories

As functional extensions of circuit breakers, accessories enhance control options and broaden protective capabilities. These components are indispensable parts of the breaker system and play critical roles in both control and protection. Common accessories include auxiliary contacts, alarm contacts, shunt releases, undervoltage releases, electric operating mechanisms, and external rotary handles.

Auxiliary contacts

They are primarily used to indicate the open or closed status of the circuit breaker. However, they do not reflect whether a trip occurred due to a fault. In terms of structure, molded case circuit breakers (MCCBs) with a frame current of 125A typically use a single-break changeover contact. For frame currents of 250A and above, a bridge contact design is adopted, with a conventional thermal current of 3A. Breakers rated at 400A or higher can be equipped with two normally open and two normally closed contacts, with a thermal current of 6A.

Alarm contacts

They are used to signal that the breaker has tripped due to fault conditions such as overload, short circuit, or undervoltage. These contacts are not intended for high-current applications. Their typical working currents are AC 380V at 0.3A and DC 220V at 0.15A, with maximum heating currents usually limited to between 1A and 2.5A.

Shunt releases

Shunt releases allow for remote tripping of the breaker. The shunt release coil operates independently of the main circuit voltage and functions in a short-duration mode. The coil should not remain energized for more than one second, as extended energization could result in coil burnout. To prevent this, a microswitch is connected in series with the coil. When the release is activated, the armature engages and opens the microswitch, interrupting the control circuit. Even if the trip button is held down, the coil will not continue to energize. After the breaker is reset and closed again, the microswitch returns to its normally closed position. Shunt releases are available in a variety of control voltages and frequencies to accommodate different power supply conditions.

Undervoltage releases

Undervoltage releases are designed to protect circuits and equipment from low-voltage conditions. The coil is connected to the line side of the breaker, and the breaker can only be closed once the undervoltage release is properly energized. If the voltage is insufficient, the breaker cannot close. Therefore, users must ensure that the rated voltage of the release matches the actual line voltage. The typical operational range for undervoltage releases is between 70% and 35% of their nominal rated voltage. Like shunt releases, they are available in different voltages and frequencies for various applications.

The figure below provides a comprehensive overview of these accessories and their installation configurations.

Flying Arc Distance of Circuit Breaker

When a circuit breaker interrupts a large short-circuit current, an electric arc is generated as the moving and stationary contacts separate. Part of this arc, along with ionized gas, may be expelled through the arc vent on the power-supply side of the breaker.

Because the arc carries extremely high current, it poses a serious risk. It can lead to phase-to-phase short circuits or phase-to-ground faults if it comes into contact with exposed conductive parts or grounded metal enclosures.

To ensure safe operation, users must consider the flying arc distance when selecting a circuit breaker. This is especially important in confined spaces such as distribution boxes or switchgear cabinets. If installation height or internal cabinet spacing is limited, choosing a breaker with a zero flying arc design or adequate arc isolation is essential to avoid arc-related accidents.

Proper consideration of arc control measures helps ensure electrical safety, protect equipment, and prevent hazardous failures in high-current environments.

Conclusion

Selecting the right molded case circuit breaker is essential for ensuring system safety, reliability, and performance. From understanding rated current and insulation voltage to choosing appropriate accessories and accounting for flying arc distance, each parameter plays a critical role in protecting your electrical infrastructure.

Derlicn Electric’s DLM1 Series MCCBs are designed to meet the diverse needs of modern low-voltage power distribution systems. With wide frame current options ranging from 63A to 1600A, high breaking capacities (up to 50kA), robust insulation performance, and a full range of functional accessories, the DLM1 Series offers exceptional versatility, safety, and value.

Whether you’re an OEM, panel builder, or end user, the DLM1 Series is engineered to deliver consistent protection and operational reliability—even in the most demanding environments.

👉 Ready to upgrade your system? Contact us today for a tailored quotation or technical consultation.

📧 Email: info@derlicn.com

🌐 Learn more about our product: DLM1 series molded case circuit breaker

Derlicn Electric — Powering Protection with Precision.

Table of Contents

Have you Any Questions?

Can’t find an answer to your question, or want more information about our products? If so, please feel free to get in touch with our professional team. We’re here to help you drive your projects to success.